Case

MV Split, Croatia

BEFORE Aerovit Installation

- Vessel: M.V. SPLIT

- Type: Bulk carrier

- Boiler: TPK Nova, flame tube

- Year of construction: 1994

- Fuel: Heavy Fuel Oil, 380 cst

- Problems: Large deposits of soot have been formed inside the flame tubes requiring frequent stoppage of the boiler for cleaning, causing time loss and increased fuel consumption.

- Date of installation: April 2008

BEFORE

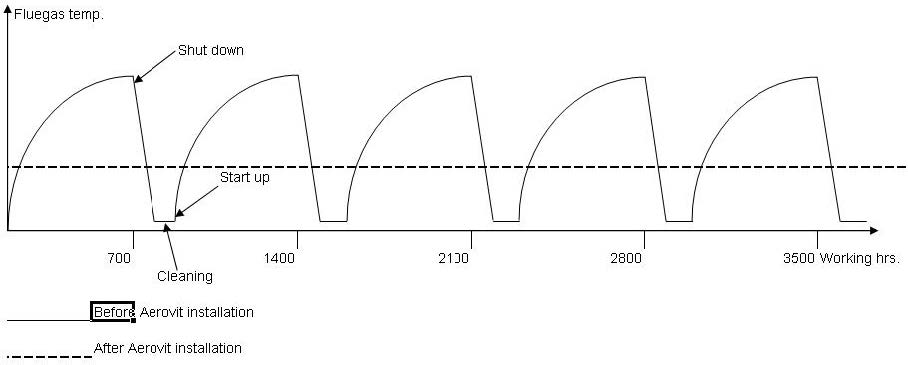

The boiler had to be stopped for cleaning every 700-1000 hours of work, depending on the duration of the voyage.

Upon arrival at ports, engine crew were busy with boiler cleaning, so they had less time for other necessary maintenance work.

AFTER Aerovit Installation

After 700 hours of operation, with AEROVIT installed, the boiler was opened for internal tube control. All tubes were clean and passable as if they were new.

After installation of AEROVIT in April 2008 the boiler has been working more than 6000 hours and has not been stopped for manual cleaning.

Mr. Zdravko Kesić

Technical superintendent from M.V. Split

„Because there is no need anymore for boiler cleaning, our crew has more time for regular maintenance work and this implies significant cost savings. Also due to efficient boiler performance, fuel savings has been noticed“

Want to know more?

Download case

If you want further information about the case you can find it here