Grästorp, Sweden

Before Aerovit installation

Fuel

Wood chips and Salix

Boiler

3.5 MW – installed 2002

Soot-blower

The boiler was delivered with a soot-blowing system at the top of the boiler. The system was from another supplier and therefore without the patented cooling system

- 9 pcs. valves on 1st stroke countercurrent

- 5 pcs. valves on 2nd stroke wake

- 7 pcs. valves on 3rd stroke countercurrent

Efficiency

Mechanical cleaning was necessary several times per month – the pipes were not kept clean.

Initiative

It was decided to replace the soot-blowing system on the 1st stroke. AEROVIT soot-blowers on a new boiler door were delivered February 2003.

AFTER Aerovit Installation

Result

- Mechanical cleaning only necessary twice a year.

- The pipes in 1st stroke are now kept clean.

- The pipes in 2nd stroke are now kept fairly clean.

- The pipes in 3rd stroke are not kept clean.

Future

If the remaining soot-blowing system is replaced with AEROVIT valves, it is to be expected that there will be a need for mechanical cleaning only once every 2 or 3 years.

Service carried out on all valves after 4 years in operation

The 12 valves without the patented cooling system

All 12 valve diaphragms were burned or melted, cracked and rigid – clearly affected by the heat from the boiler’s turn box. All diaphragms had to be replaced.

Corrosion in the shot tube of the valves – obviously affected by corrosive flue gas. The shot tube is almost sooted up in consequence of dysfunction.

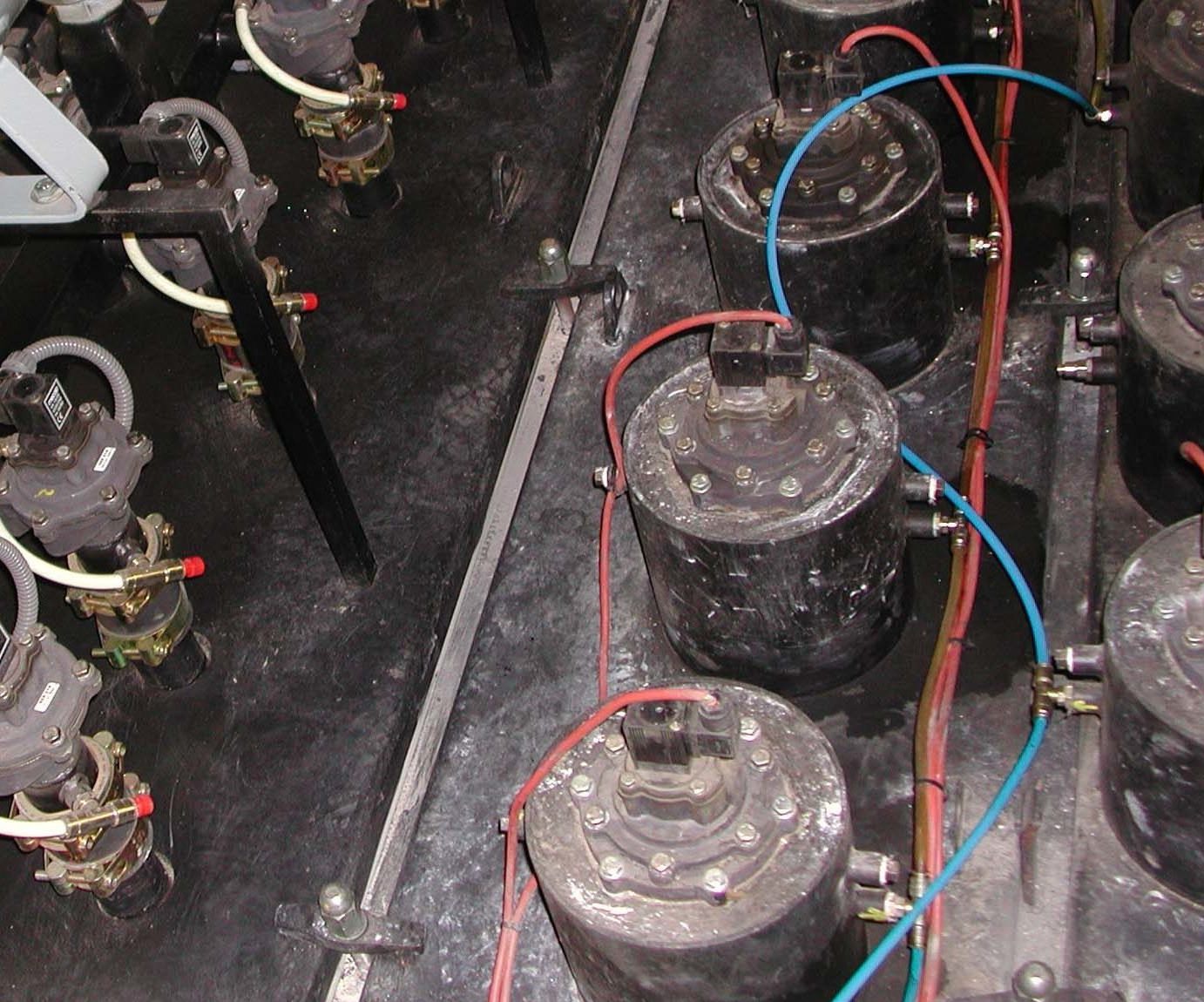

The 9 valves from Aerovit with the patented cooling system

The AEROVIT SYSTEM – with cooling – on 1st stroke has faultless function. All 9 valves and valve diaphragm are in good condition and require no replacement. Clear result of AEROVIT’s patented system with cooling air.

Download case

If you want further information about the case you can find it here