ComBio, Brazil

The Challenge

At Klabin S.A., ComBio faced a critical challenge in maintaining high steam availability while minimizing operational shutdowns. The biomass mixture, primarily wood chips and sugarcane bagasse, caused varying rates of soot deposition in the boiler’s thermal exchange tubes.

Without proper cleaning, soot accumulation led to efficiency losses, decreased steam production, and ultimately, revenue reductions.

Initially, the boiler system required a full shutdown every three months for manual cleaning, disrupting production and profitability.

ComBio sought a solution that would extend the cleaning interval to just one annual shutdown while ensuring optimal boiler efficiency.

The Solution

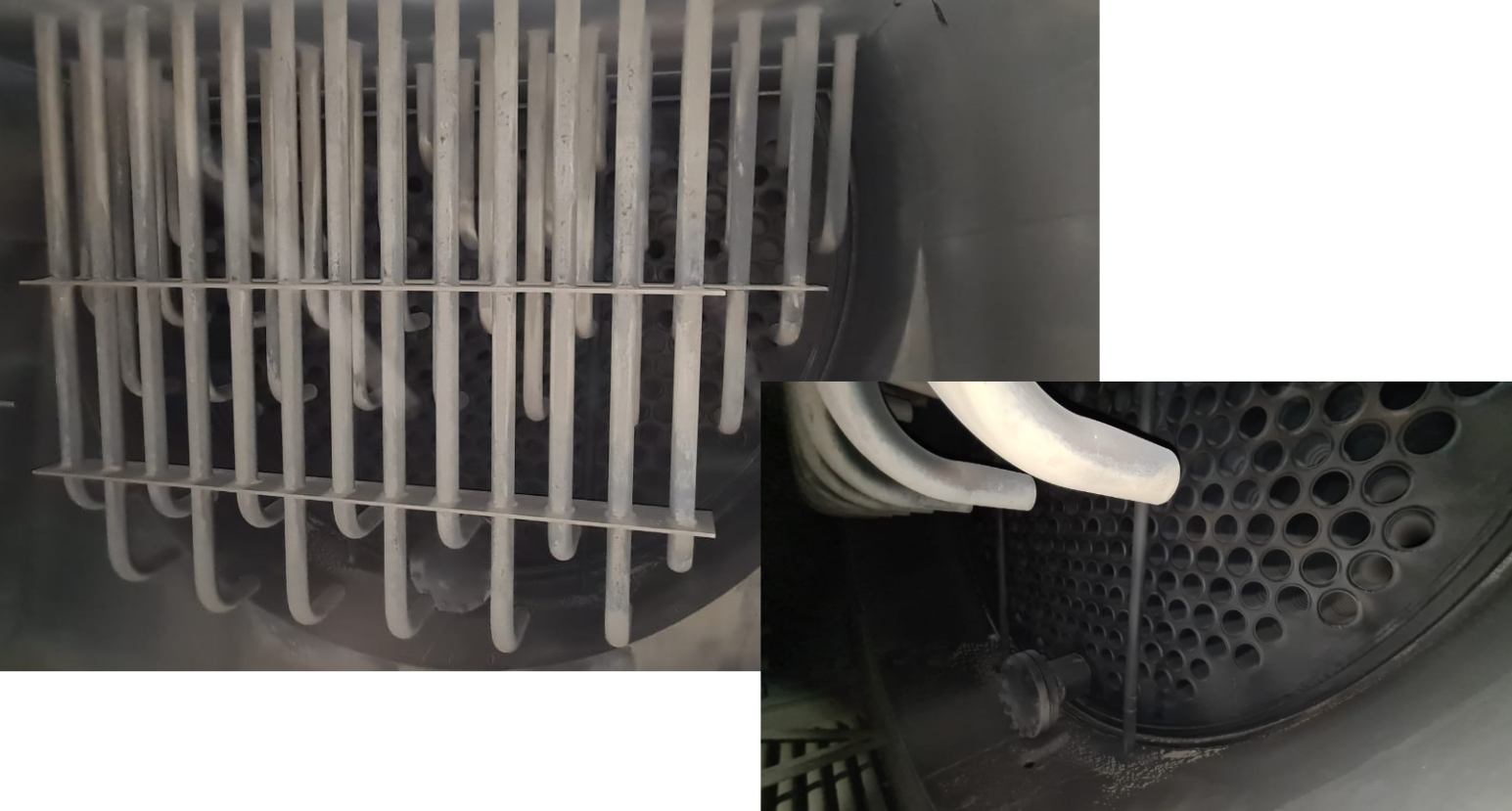

To address these challenges, ComBio, through DanPower, implemented the Aerovit ShockClean System at Klabin’s plant. The selected boiler, a mixed-type unit with a 37-ton-per-hour steam capacity, was fitted with 49 Aerovit valves in its firetube section.

The system was installed at the top of the rear smoke box, where a grid of pipes was used to maintain the optimal distance between the soot blower and tubeplate, ensuring maximum cleaning efficiency. By automatically removing soot deposits, the Aerovit system prevented buildup that would otherwise lead to performance deterioration and unplanned downtime.

Statement from ComBio

The Results

By integrating the Aerovit ShockClean System, ComBio successfully optimized boiler efficiency, minimized downtime, and achieved greater cost-effectiveness – demonstrating the system’s value in high-demanding industrial environments.

Following the installation of Aerovit ShockClean System, the steam generation plant was monitored over a one-year period. The results were clear:

Cleaner Boiler Tubes

The boiler tubes remained satisfactorily clean, significantly reducing the manual effort required during scheduled maintenance.

4x Fewer Shutdowns

Reduced the need for manual cleaning from every 3 months to just once a year, ensuring higher steam availability and lower downtime.

Stable Steam Production

Steam production remained stable, ensuring high profitability and uninterrupted operations at Klabin S.A.

Increased Profitability

By eliminating frequent shutdowns and reducing maintenance efforts, ComBio cut operational costs while ensuring steady, uninterrupted energy production for Klabin S.A.

Overview

ComBio Energia S.A. specializes in steam generation and cogeneration projects using biomass, offering industrial clients significant cost reductions and environmental benefits.

Operating in collaboration with DanPower, one of Brazil’s leading boiler manufacturers, ComBio provides efficient biomass-based energy solutions.

How does Aerovit ShockClean System work?

The Aerovit ShockClean System is an automatic cleaning solution designed to prevent soot buildup in boiler tubes, ensuring consistent efficiency and performance. It operates by releasing high-pressure pulses of compressed air into the boiler’s firetube section, dislodging accumulated soot and preventing deposits from hardening over time.

At Klabin S.A., 49 Aerovit valves were installed in the rear smoke box on a structured grid of pipes. This setup ensures an optimal cleaning distance, effectively removing soot without causing damage to the tubes. By automating the cleaning process, the Aerovit system eliminates the need for frequent manual cleaning, reduces maintenance costs, and extends boiler uptime.

Download the case story

Discover how we helped Combio to increase profitability and improve boiler efficiency.