Fjernvarme Fyn, Denmark

The Challenge

Fjernvarme Fyn faced challenges with manual cleaning procedures at its waste incineration plant in Odense.

Manual cleaning procedures were sporadic and often neglected due to competing priorities. The company had to halt operations for one week every six months for manual cleaning of the boiler.

The Solution

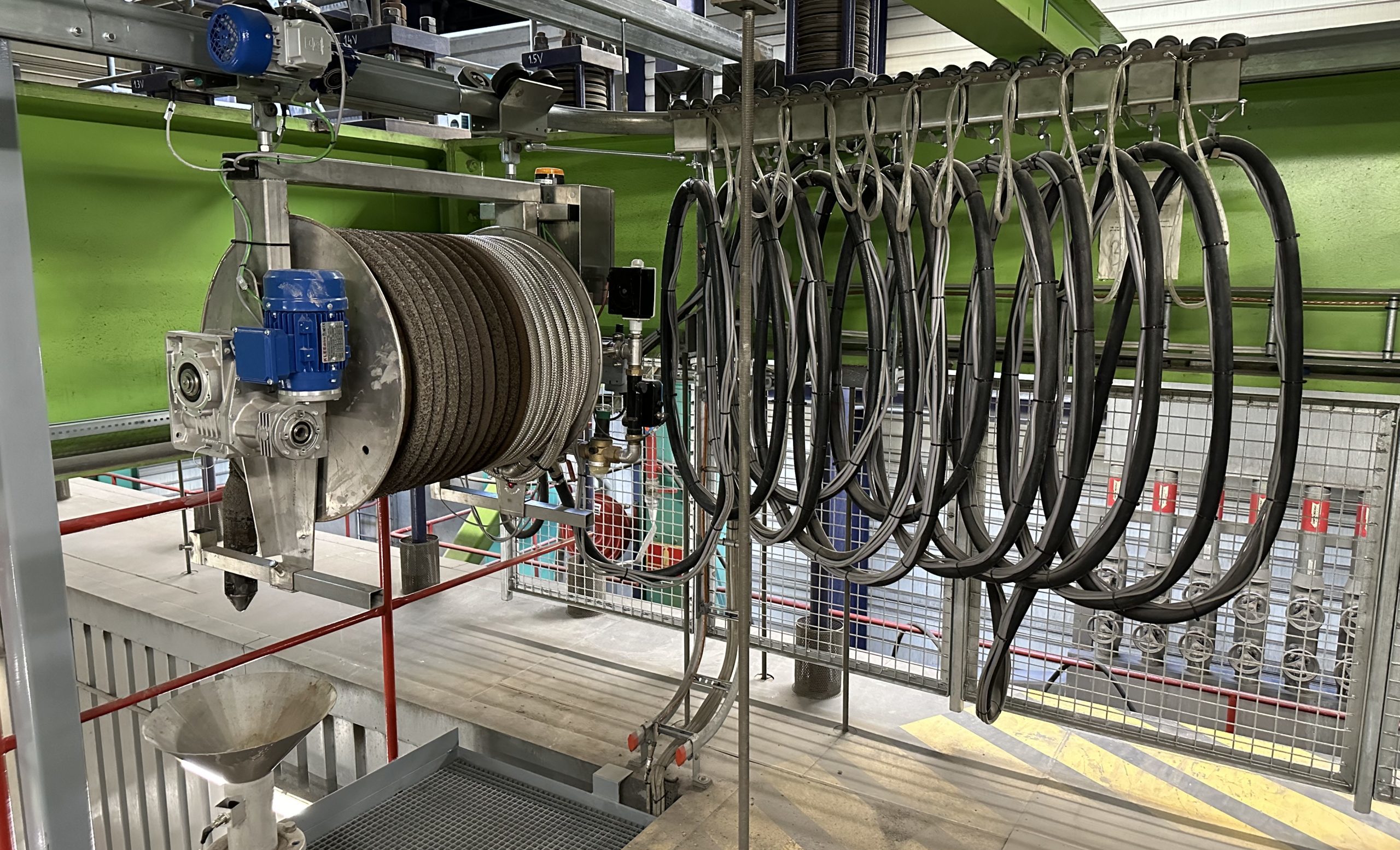

Fjernvame Fyn implemented the fully automatic Aerovit SC-Jet system in August, 2023. The SC-Jet system is controlled by a PLC system and was installed at Fjernvarme Fyn’s waste incineration plant which produces 15 MWh of electricity and 60 MWh of heat per hour. The boiler was first brought into operation in 1999 and burns approximately 450 tons of waste a day.

Aerovit SC-Jet facilitates cleaning of both the second and third boiler passes within a two-day cycle, optimizing plant cleanliness without excessively cooling the superheaters. This has led to improved boiler performance, as the reduced buildup of deposits minimized the need for unscheduled shutdowns.

How does Aerovit SC-Jet work at Fjernvarme Fyn?

The Aerovit Shower Cleaning solution is an online system capable of operating effectively at high temperatures. At Fjernvarme Fyn cleaning is performed systematically in the second and thrird passes within 2-day cycle .

Operators can now initiate cleaning

cycles with the push of a button from the control room, ensuring daily maintenance without interruptions.

Cleaning is performed by lowering the SC-jet nozzle head down into the boiler passes. During fullload operation of the incinerator, an optimal quantity of water is precisely sprayed onto the boiler walls, effectively removing the slag deposits. This process ensures efficient performance and is executed with precision.

The Results

With the SC-Jet’s automated functionality, cleaning became systematic and efficient. Operators can now initiate cleaning cycles with the push of a button from the control room, ensuring daily maintenance without interruptions. Implementation of SC-Jet, in

collaboration with Aerovit, transformed the cleaning processes, leading to significant improvements in plant performance and cost savings. Fjernvarme Fyn seamlessly transitions from one revision to the next without any downtime, ensuring continuous energy production.

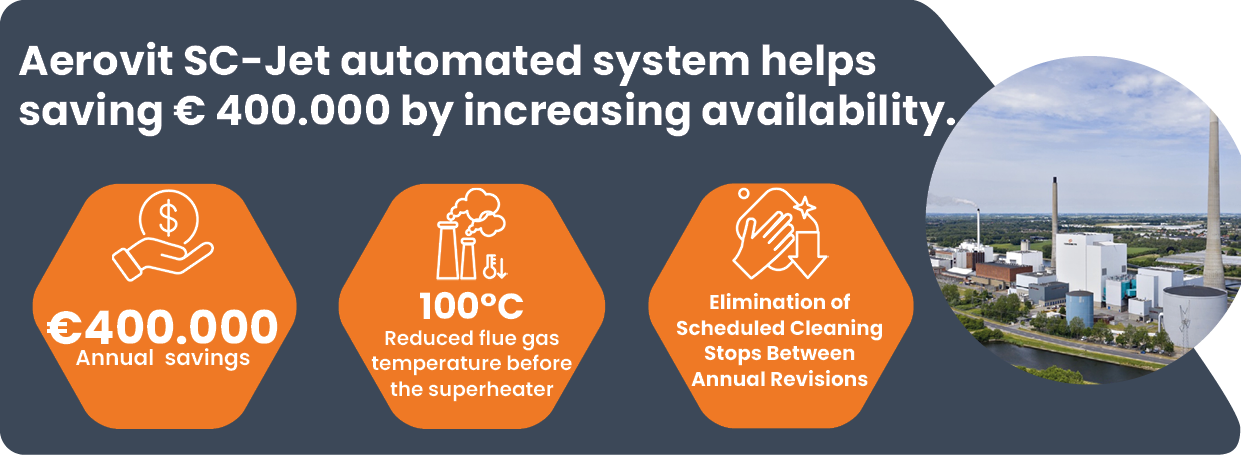

The utilization of Aerovit SC-Jet, alongside explosion cleaning, results in savings of €400,000 for every avoided shutdown of the boiler, encompassing expenses associated with cleaning (€ 200,000) and lost production income (€ 200,000).

The implementation of the Aerovit SC-Jet Shower Cleaning system led to a significant reduction in flue gas temperature before the superheater by approximately 100°C. Prior to installing the Aerovit solution, the flue gas temperature during full-load operation reached 632°C. After the SC-Jet system was implemented, the temperature dropped to 528°C, while maintaining the same operational load

Continuous Energy Production

Elimination of Scheduled Cleaning Stops Between Annual Revisions

Systematic & Efficient Cleaning

Reduced Maintenance Downtime

Easy Operation

Increased Operational Uptime

Increased Boiler Performance

No Unscheduled Shutdowns

Overview

Fjernvarme Fyn stands as Denmark’s 3rd largest district heating company, owned jointly by Odense and Nordfyn Municipality. The company operates the largest cogeneration plants on Funen, boasting a workforce exceeding 300 employees.

Renowned as one of Europe’s premier heat suppliers, Fjernvarme Fyn is one of the key contributors of the region’s energy infrastructure. With a broad service reach, the company caters to approximately 97% of the heating demands in Odense and its surrounding area, catering to over 100,000 residences, industrial facilities, and institutions.

Download case

Discover how we helped Fjernvarme Fyn saving €400.000 by increasing availability.