Aerovit SC-Jet

Shower Cleaning

Online cleaning of the open pass of boilers in waste-to-energy incinerators and biomass combustion plants

The Aerovit SC-Jet Shower Cleaning system is a cutting-edge, automated cleaning solution designed to maintain peak performance in waste-to-energy incinerators and biomass combustion plants.

By efficiently cleaning the open passes of the boilers, the flue gas temperature is reduced with 50-80˚C at the radiation boiler outlet. The SC-Jet system ensures uninterrupted operation and reduces fouling, which increases boiler efficiency.

Operating at extreme temperatures (600-1250°C), the SC-Jet cleans during full-load operation, minimizing downtime while achieving outstanding results.

Designed for new installations or retrofitting, it requires a minimal number of inlets in the boiler roof and integrates seamlessly with existing setups.

Advantages of Aerovit SC-Jet Shower Cleaning:

- Efficiency Boost

Increases boiler efficiency by 3-5% through improved heat transfer. - Temperature Reduction

Reduction of flue gas temperature by 50-80°C at the radiation boiler outlet. - Concentrated Water Jets

Reaches over 5 meters to clean surfaces effectively. - Automated Control

PLC-controlled cleaning sequences for consistent and reliable operation. - Durable Construction

Built for low maintenance costs and long-lasting performance. - Minimum inlets

The design of the SC-Jet system reduces the number of inlets to a minimum.

Aerovit SC-Jet – Nozzle Head

The Aerovit SC-Jet features a unique rotating nozzle head with six nozzles, delivering concentrated water jets that reach over 5 meters onto heating surfaces to ensure efficient deposit removal.

The laminar water jets maintain their shape and strength over long distances, which ensures minimal turbulence and water dispersion. Upon contact with the hot surfaces, the large water droplets expand instantly by 1,700 times, transitioning from liquid to gaseous form in accordance with the natural laws of physics.

The large droplets penetrate the micro-openings in the fouling and rips off the fouling without requiring additional power or pressure.

Advantages of Aerovit SC-Jet Nozzle Head

- Unique nozzle head

The innovative design delivers precise and effective cleaning. The nozzle head sprays the water more than 5 meters for less water consumption. - Low pressure operation

To prevent the water jets from splitting and remaining intact. The cleaning process is gentle and does not wear down the pipes. - No excess water

The water jets are directed exactly where needed to achieve optimal cleaning. Which also reduces the frequency of cleaning. - Explosive vaporization

The water instantly evaporates on contact with the hot boiler surfaces, creating a power ful force that removes deposits from the walls.

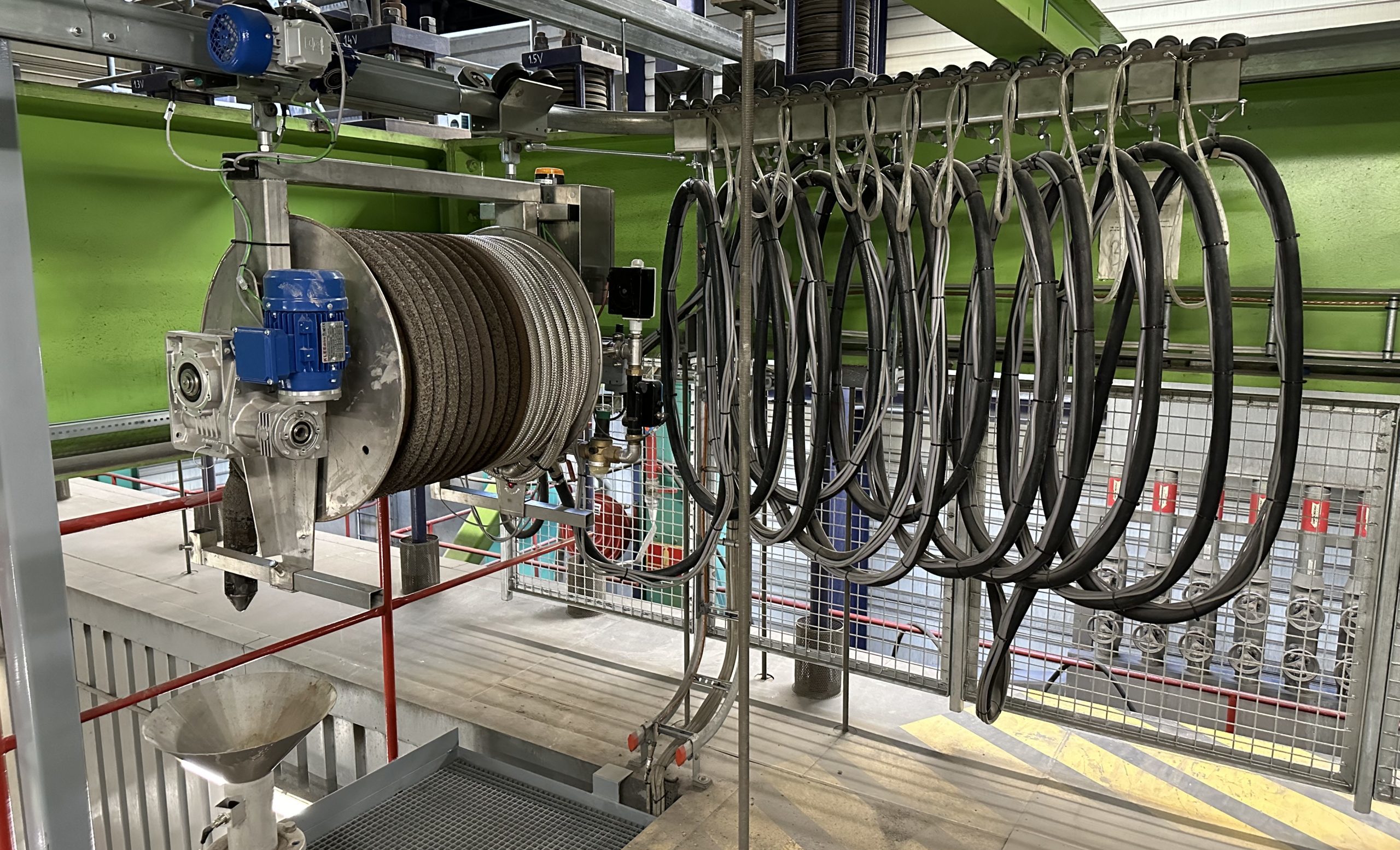

Conveyor system

The conveyor system consists of a rail system, equipped with a conveyor motor controlled by the electrical control system for automatic operation.

The positioning of the cleaning is done 100% automatically with a built-in encoder

for a millimeter hose compensation for precise operation.

PLC Controller

The PLC/VFD is housed within a painted electrical cabinet equipped with an integrated cooling system and temperature monitoring for optimal performance and reliability. The system is configured with Profinet installation and is prepared for a 220-volt UPS supply to ensure uninterrupted operation.

An interactive display provides real-time status updates, allowing operators to monitor the cleaning sequence and verify its accuracy. The system controls critical functions, including the cleaning depth within the boiler, selection of boiler sections to be cleaned, cleaning process speed, and the required water volume.

Patented Cleaning Solution

Aerovit’s innovative SC-Jet Shower Cleaning solution is protected by a patent, ensuring its unique and effective cleaning approach.

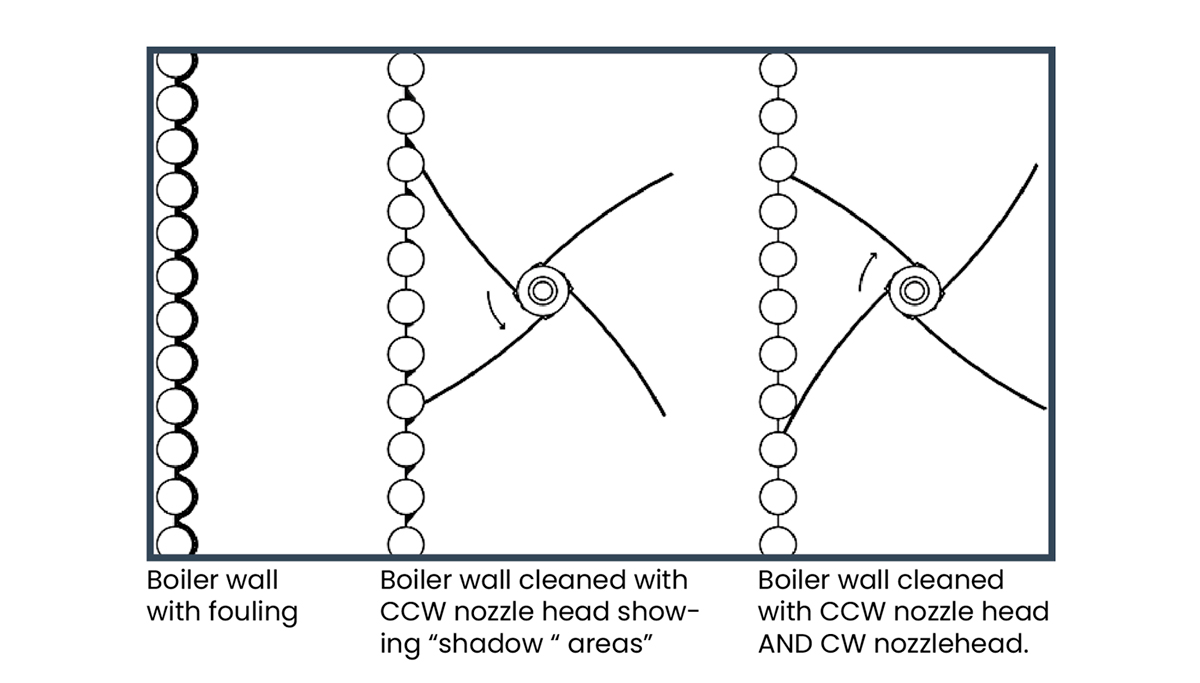

The system utilizes two nozzle heads: one rotating clockwise and the other counterclockwise. This approach ensures optimal and thorough cleaning, effectively targeting hard-to-reach areas, including previously unaddressed shadow areas.

How does it work?

The Aerovit SC-Jet Shower Cleaning system directs 4-6 concentrated water jets through the unique nozzle head over a distance of more than 5 meters to effectively clean the heating surfaces of the boiler during full-load operation of the incinerator.

This system is designed to function at elevated temperatures commonly found in the waste-to-energy plants (ranging from 600 to 1250°C). The operation is fully automated, ensuring seamless and uninterrupted performance.

Get our product sheet

Download our product sheet with information about Aerovit SC-Jet Shower Cleaning solution.

Contact us today

-

Søren Amby Jørgensen

- Management, Aerovit A/S

- E-mail: saj@aerovit.dk

-

Alina Nielsen

- Secretary, Aerovit A/S

- E-mail: aln@aerovit.dk

-

Heidi Seiger Thomsen

- International sales, Aerovit A/S

- E-mail: hst@aerovit.dk