Aerovit Soot Blower

The Aerovit Soot Blower is a system for keeping boilers clean during operation

The Aerovit Soot Blower solution is a highly efficient cleaning system designed to maintain high boiler performance by removing soot and ash deposits.

The well-proven cleaning solution ensures uninterrupted boiler operation and reduces the need for manual cleaning.

Using pure compressed air, the Aerovit Soot Blower delivers powerful, timer-controlled shock waves, that clean key components like biomass boilers, economizers, heat exchangers, marine boilers, catalyst elements, and thermal oil coil boilers.

In just fractions of a second, 450 liters of high-compressed air is released through the Aerovit valve, effectively dislodging sediments and ensuring consistent cleanliness throughout the boiler system.

Unlike traditional cleaning methods, this system operates continuously during normal boiler operation, minimizing downtime and improving overall efficiency.

Features:

- Payback time in 3-24 month

High return on investment through energy savings and reduced maintenance. - Proven higher efficiency and boiler output

Enhances heat transfer and boosts boiler performance. - Reduce manual cleaning and boiler shutdowns

Reduces downtime with automated continuous cleaning. - Reduce fuel consumption per produced MW

Optimizes use of fuel for energy production. - Reducing CO2 emission

Supports sustainability by lowering fuel consumption. - Robust design with few moving parts

Durable and low-maintenance for long-term use.

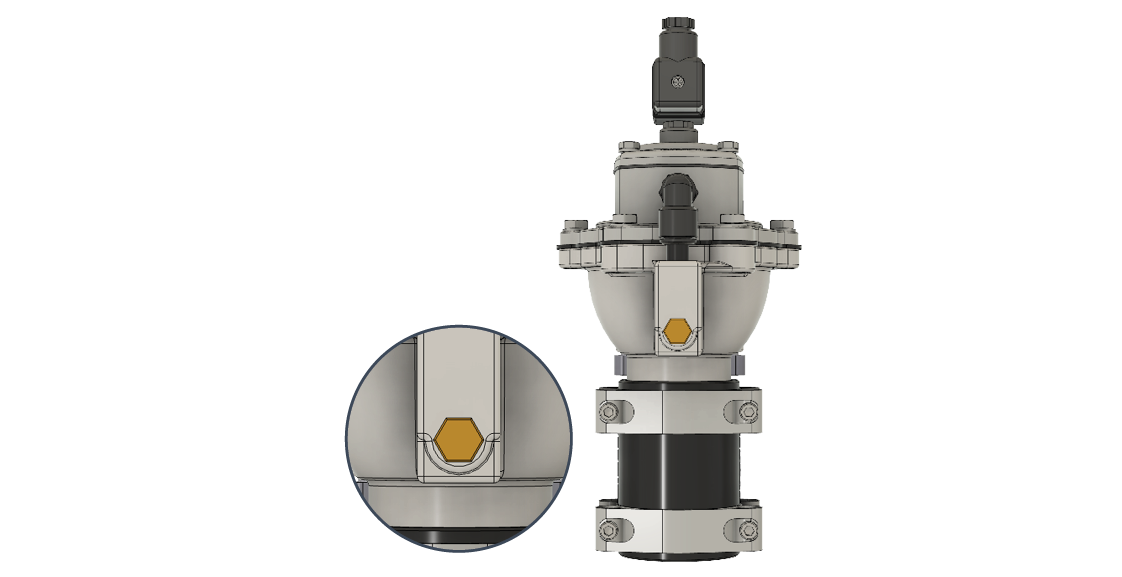

Aerovit Valve

The unique Aerovit valve unit integrates a cooling system and a soundsilencer, making it more compact and resilient. This innovation enhances durability and increases reliability during operation, while still ensuring a low sound level.

The Aerovit Soot Blower system is highly adaptable, with no limits to its size or scope. The number of blast valves, the supply of compressed air, and the timer controller can be customized to meet specific operational requirements.

The Aerovit Soot Blower system is a versatile solution, that seamlessly integrates with both new and existing biomass boilers, catalysts, heat exchangers, and economizers.

Each system is customized to meet the specific needs and requirements of the customer. Ensuring optimal performance and reliability.

Problems caused by soot buildup

Soot accumulation reduces heat transfer, increases fuel consumption, and can cause uneven heat distribution in the boiler.

Over time, this leads to decreased efficiency, higher operating costs, and a greater risk of unplanned shutdowns for manual cleaning or repairs.

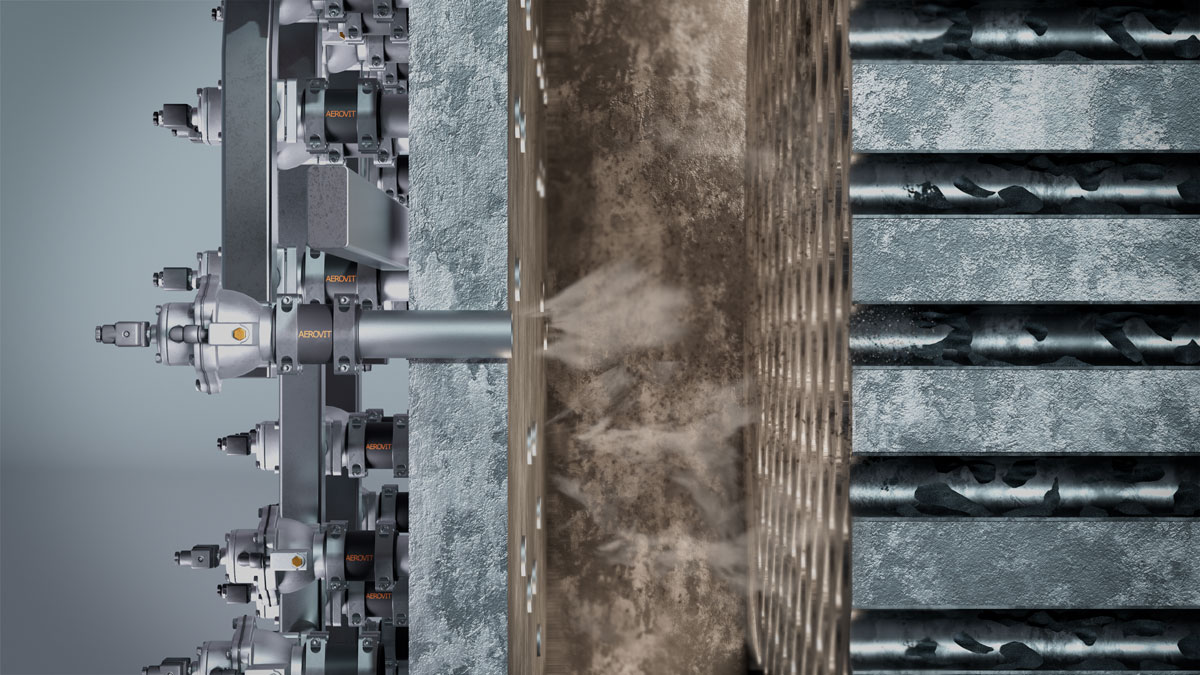

How does a soot blower work?

The Aerovit soot blower system utilizes powerful shock waves of high-compressed air to effectively clean the convection part.

In a fraction of a second, 450 liters of compressed air is released through the Aerovit valve, generating a powerful shock wave blast, that removes soot and ash deposits.

This continuous, automated cleaning process prevents buildup in boiler tubes and compartments, maintaining peak efficiency without requiring shutdowns. The system operates continuously at high temperatures, allowing for uninterrupted boiler performance while maintaining cleanliness and efficiency.

Get our product sheet

Download our product sheet with information about Aerovit Soot Blower Cleaning Solution.