50-60% increase in steam production, ROI within 3 months

The Challenge

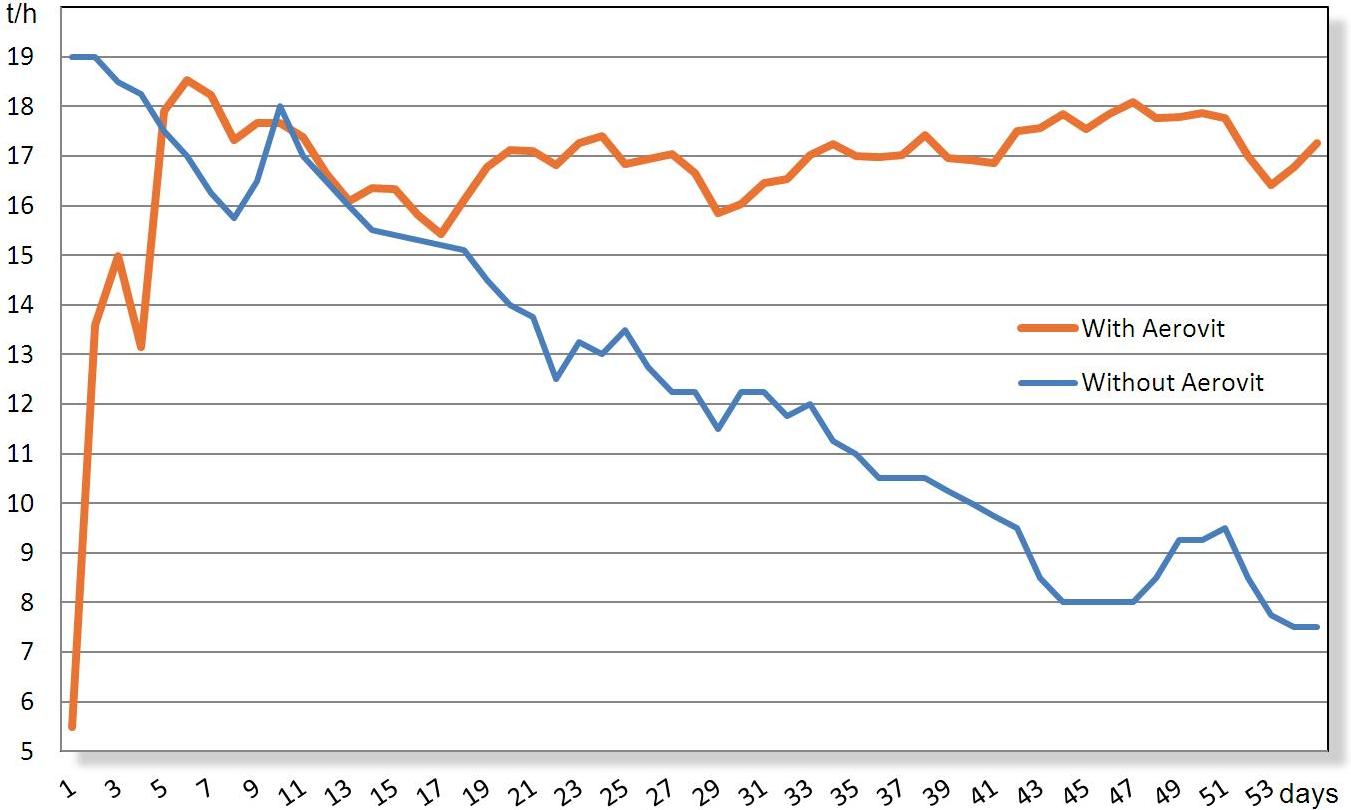

Within just two months of operation, catalyst dust would fully cover the boiler tubes, drastically reducing steam output from 19 t/h to only 7.5 t/h per boiler.

Manual cleaning was not feasible, as it would force a complete shutdown of the refinery—a highly costly and disruptive outcome. As a result, the boilers operated far below capacity, causing major inefficiencies.

The Solution

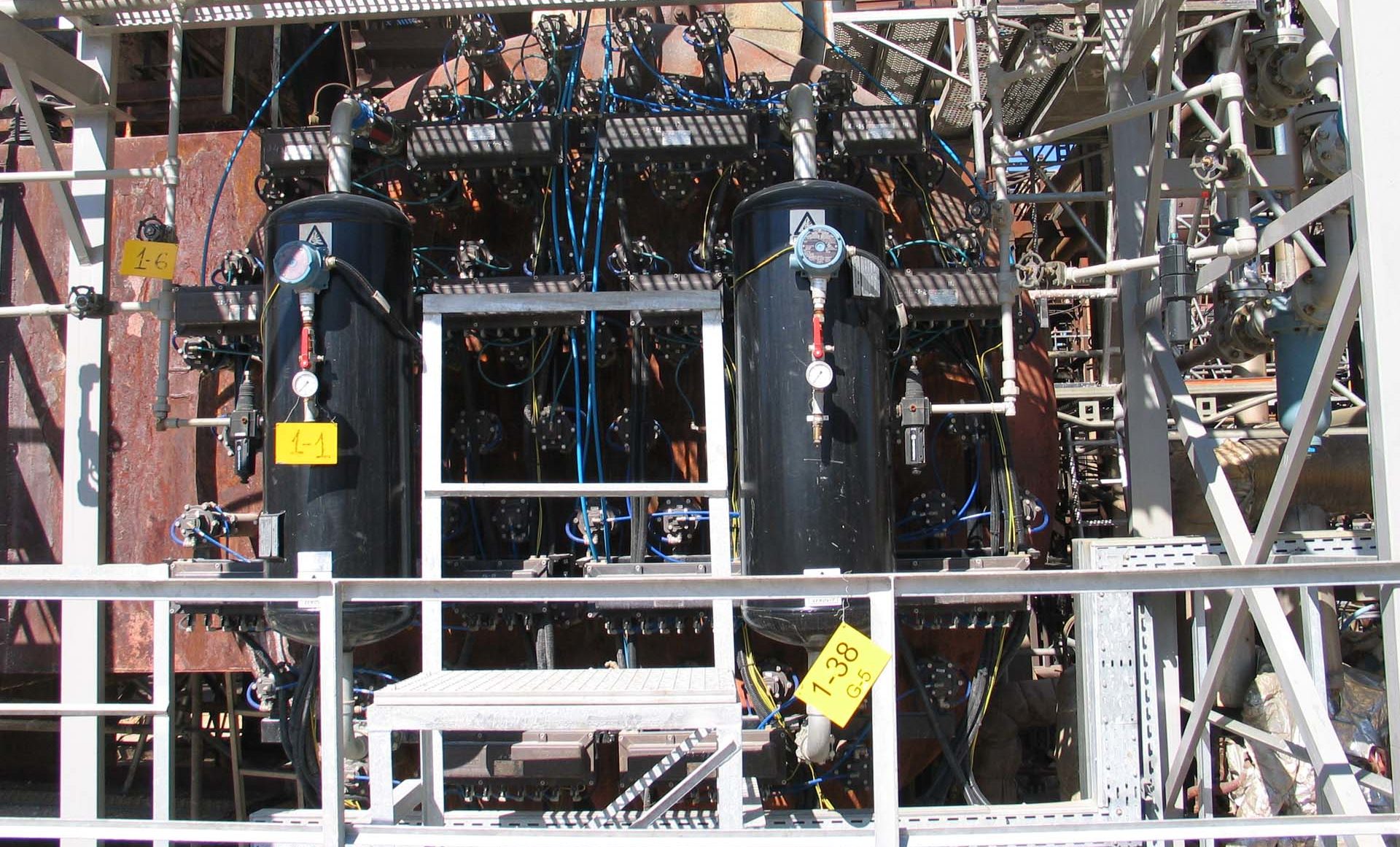

To eliminate dust build-up without interrupting operations, Orlen installed Aerovit ShockClean System on both boilers.

These systems were integrated into the Fluid Catalytic Cracking Unit and allowed for online cleaning, removing the need for manual intervention.

Statement from Orlen

How does Aerovit ShockClean System work at Orlen Refinery?

Aerovit ShockClean System were mounted directly on the heat recovery boilers KU-401/1 and KU-401/2. The system delivers powerful pulses of compressed air to dislodge catalyst dust from the tube surfaces. This keeps the heat transfer surfaces clean during operation, preventing efficiency loss and maintaining high steam output.

Post-installation, steam production stabilized at around 17 t/h per boiler – a significant improvement from the dust-clogged state of 7.5 t/h.

The total output for both boilers rose to 34 t/h, a gain of 19 t/h, which would otherwise have required approx. 11.6 million litres of oil per year to produce on a backup boiler.

The Results

Steam production increased by 50-60%

Return of investment in 3 months.

Operational output increased by 127%.

No shutdowns required for manual cleaning

Overview

Orlen Lietuva, a major oil refinery, operates two boilers critical for steam generation. Before installing Aerovit cleaning solution, catalyst dust accumulation on heat recovery boiler tubes severely reduced steam output and efficiency. Manual cleaning was not an option due to the risk of refinery shutdown.

As part of their modernization program, Orlen installed Aerovit ShockClean System on both boilers. The result was a 50–60% increase in steam production and a return on investment in just three months.

Download the case story

Discover how we helped Orlen to increase steam production and operational output by 127%. ROI was achieved in only 3 months.