Aerovit A75 – Surface Cleaning

Surface Cleaning

The Aerovit Surface Cleaning is specifically designed to prevent blockages at the inlet of the boiler’s convection part.

Over time, ash and soot can accumulate at the tube plate, where flue gases first enter the convection part. This buildup restricts flow, forcing flue gas through fewer open tubes and increasing velocity, ultimately reducing heat transfer efficiency and raising operational costs.

Installing the Aerovit Surface Cleaning valve significantly extends the interval between shutdowns for manual cleaning. This cleaning solution minimizes unscheduled downtime and helps maintain optimal boiler performance.

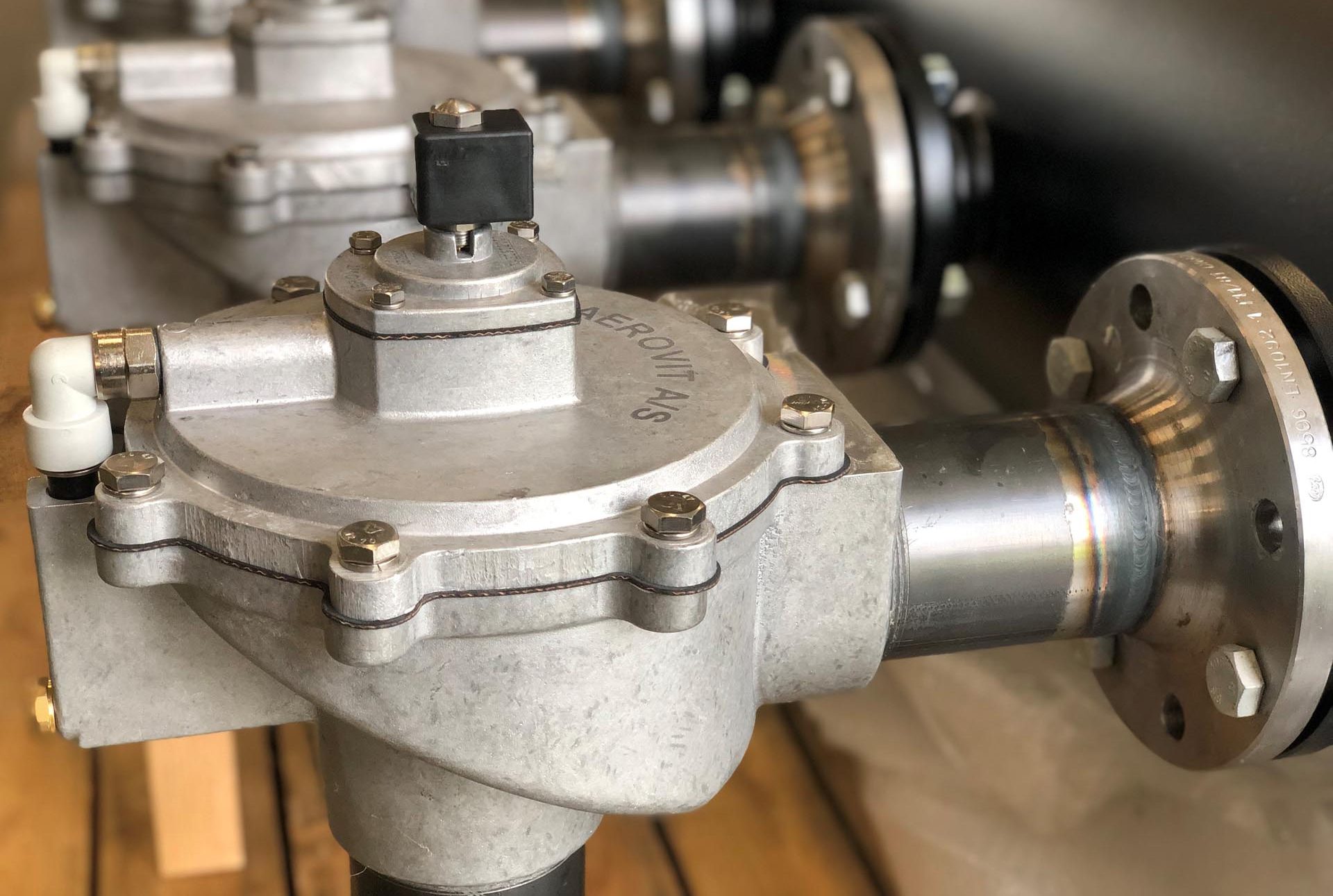

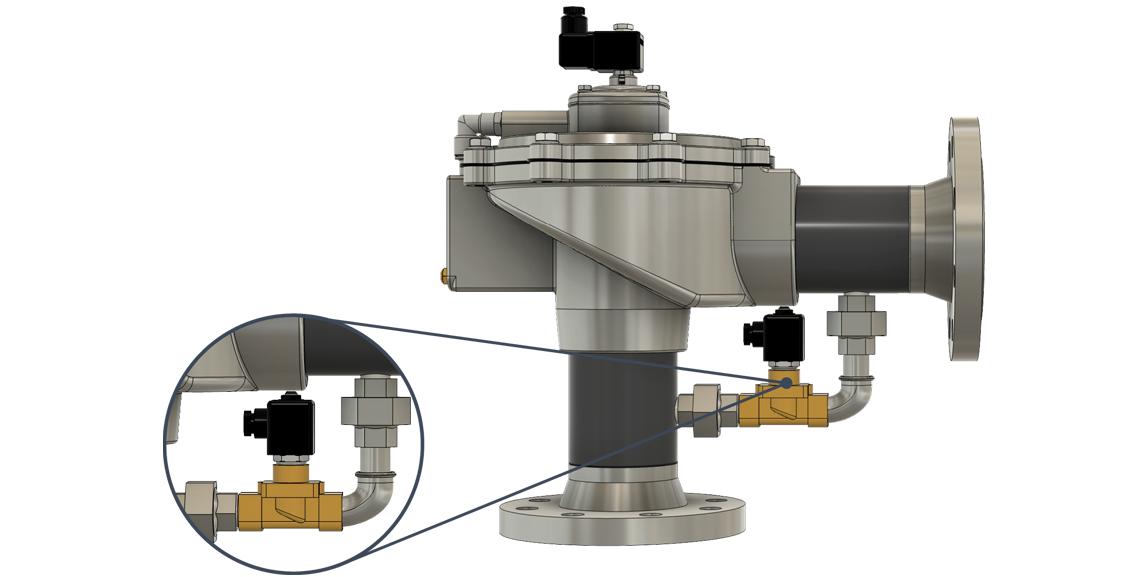

The Aerovit Surface Cleaning valve is a 3” valve with an integrated bypass valve that keeps it free of deposits and fully functional before each cleaning cycle.

In addition to the tube plate, it can clean larger surfaces such as water tube screens and flat horizontal fluegas ducts.

Features:

• Prevents clogging at the inlet of the boilers convection part

Reduces flue gas velocity and maintains stable heat transfer efficiency.

• Proven higher efficiency and boiler output

Enhances heat transfer and boosts boiler performance.

• Reduce manual cleaning and thus boiler shutdowns with 80-100%

Reduces downtime with automated, continuous cleaning.

• Reduce fuel consumption per produced MW

Optimizes use of fuel for energy production.

• Reducing CO2 emission

Supports sustainability by lowering fuel consumption.

• NC-Valve for pre-cleaning

Ensures a clean shockwave.

• Low maintenance costs

Designed for durability with minimal wear parts to reduce service intervals.

Aerovit NC-Valve

The NC-Valve plays a critical role in maintaining system efficiency. By automatically clearing the exhaust pipe before each activation, it prevents residue buildup and ensures a clean shockwave.

Designed with durability in mind, the NC-Valve operates only just before the actual shockwave is initiated. Ensuring safe and efficient cleaning.

Challenges caused by soot and ash buildup

Ash and soot buildup at the tube plate restrict flue gas flow, reducing heat transfer and increasing fuel consumption.

This localized blockage creates uneven gas distribution, decreasing boiler efficiency and raising the risk of unplanned shutdowns for manual cleaning or maintenance.

How does the Aerovit Surface Cleaing work?

The valve delivers a powerful shockwave by rapidly releasing 900 liters of compressed air, effectively removing ash deposits and soot buildup at the boiler’s tube plate before they settle.

The shockwave is precisely timed and controlled by an integrated timer system, ensuring consistent and targeted cleaning performance.

To protect internal components, the NC bypass valve clears the exhaust pipe before each activation, preventing residue buildup and ensures a clean shockwave.

Get our product sheet

Download our product sheet with information about Aerovit Surface Cleaning.

Contact us today

-

Søren Amby Jørgensen

- Management, Aerovit A/S

- E-mail: saj@aerovit.dk

-

Alina Nielsen

- Secretary, Aerovit A/S

- E-mail: aln@aerovit.dk

-

Heidi Seiger Thomsen

- International sales, Aerovit A/S

- E-mail: hst@aerovit.dk