Jaycorp, Malaysia

The Challenge

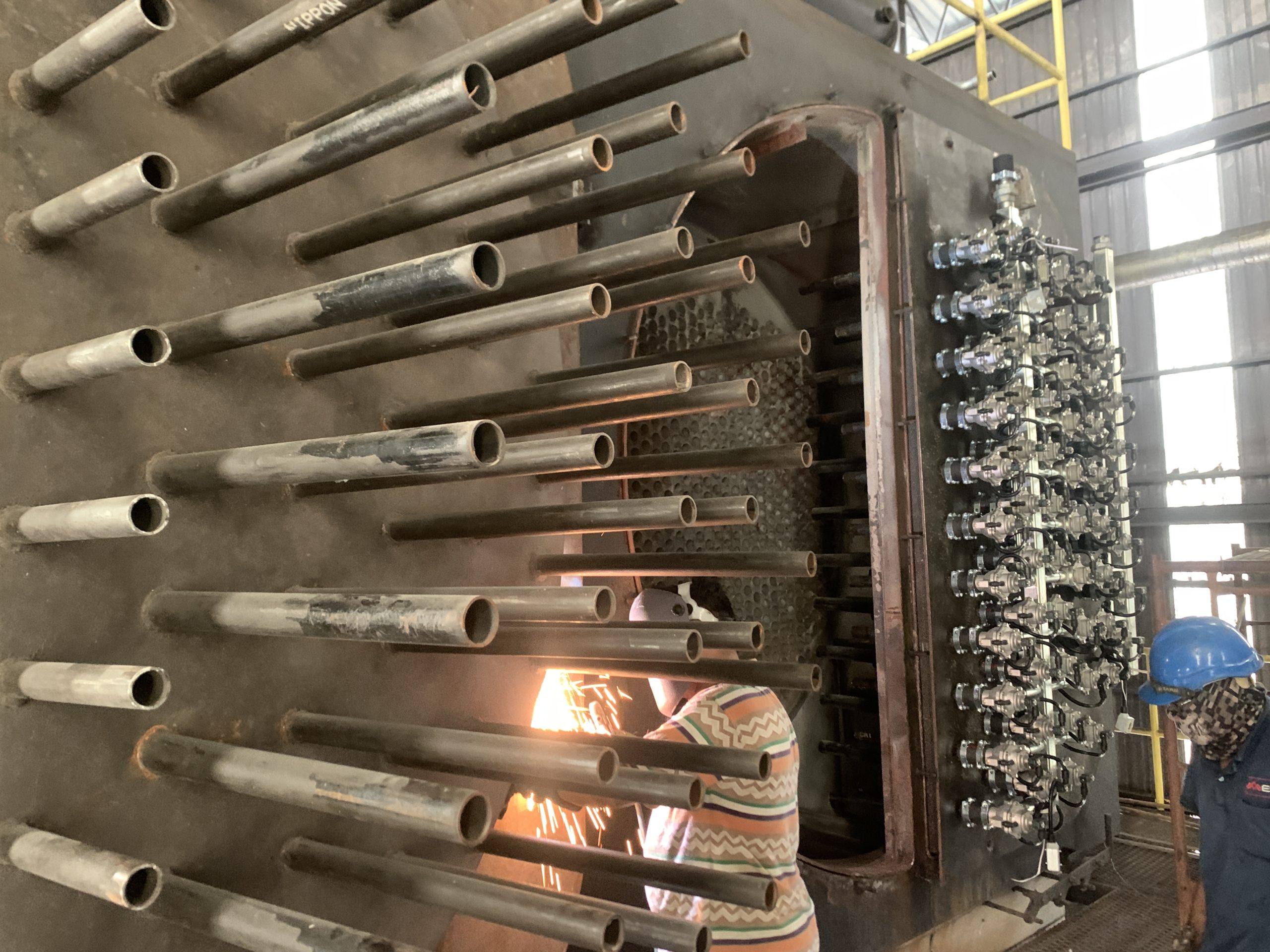

The primary issue Jaycorp faced was the frequent clogging of fire tubes in their combi boiler, due to the high ash content in their fuel. The steam plant utilizes a combi (water tube and fire tube) biomass boiler to achieve a higher efficiency compared to most biomass boilers.

However, the fire tubes became the bottleneck of operations when Jaycorp switched to using shredded Empty Fruit Bunch (EFB) as a fuel source, which is high in ash content. This issue caused their 35-ton boiler, designed to produce up to 29 tons of steam per hour, to operate far below capacity, at times generating as little as 7 tons of steam per hour. The buildup of ash in the fire tubes not only reduced thermal efficiency but also required costly manual cleanings every three weeks, each costing the company up to €20.000 in downtime and lost production.

This boiler has been in operation since 2007 and was achieving less than 5.000 hours of plant availability annually before the Aerovit ShockClean System implementation.

The Solution

In search of a more effective cleaning solution, Aerovit ShockClean System was discovered. After visiting a local plant in Malaysia to see how Aerovit ShockClean System works, Jaycorp decided to implement Aerovit’s technology in June 2024.

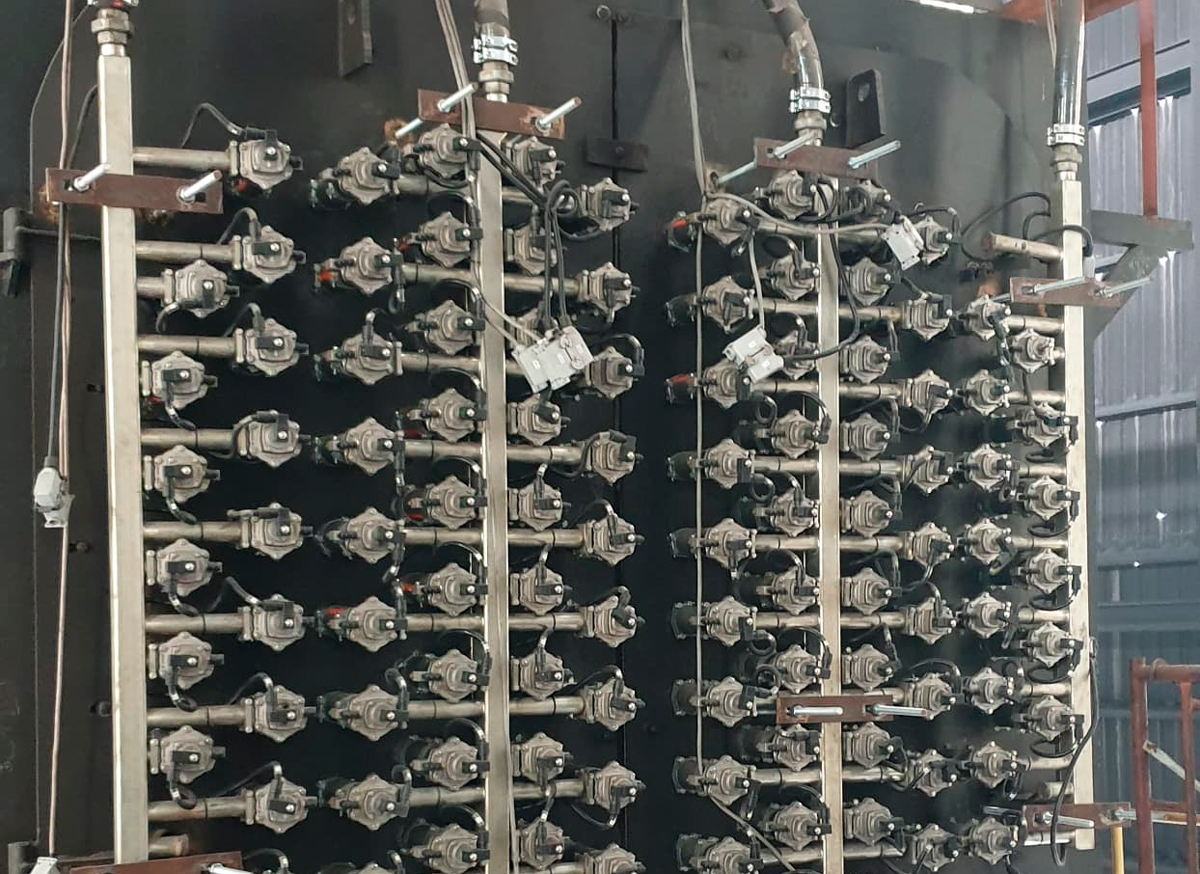

The Aerovit ShockClean System provided a crucial advantage: continuous cleaning of the fire tubes without the need for plant shutdowns.

The Aerovit ShockClean System performs cleaning 24 hours a day with a 2-minute interval per blow. This automated system ensured that the fire tubes remained clean, preventing the severe clogging that had previously hampered production.

The Results

The implementation of Aerovit’s ShockClean System has been a game-changer for Jaycorp. Not only has it resolved the long-standing issue of fire tube clogging, but it has also significantly boosted the plant’s operational efficiency and reduced costs. The results so far have been overwhelmingly positive and Jaycorp are now able to offer improved services to its clients.

Since implementing Aerovit ShockClean System, Jaycorp has seen remarkable improvements in both efficiency and cost savings, eliminating minimum €170.000 annually in cleaning-related expenses. This figure is derived from the elimination of 17 manual cleaning cycles per year, each costing between €10.000 and €20.000 due to production downtime and operational disruptions. By automating the cleaning process, the Aerovit system has not only reduced costs but also enhanced steam production and plant reliability, further improving operational efficiency.

Extended Cleaning Cycles

Before Aerovit ShockClean System, Jaycorp shut down every three weeks after producing 6.000 tons of steam. Now, they can reach 11.000 tons before a shutdown, which is mainly for maintenance rather than cleaning.

Increased Thermal Efficiency

Cleaner fire tubes have boosted heat transfer, improving thermal efficiency and reducing biomass consumption.

Operational Reliability

Plant availability has improved significantly, increasing by 300 operational hours annually. Jaycorp’s clients, including continuously operating palm oil refineries, now enjoy a dependable and uninterrupted steam supply.

Cost Savings

Reduced manual cleaning frequency has led to an ROI of less than a year, with savings in downtime and operations amounting to tens of thousands of euros per cycle.

How does Aerovit ShockClean System work at Jaycorp?

The Aerovit ShockClean System operates continuously at Jaycorp’s biomass steam plant to maintain optimal boiler performance.

By delivering precisely-timed bursts of compressed air directly into the fire tubes every two minutes, the system prevents ash buildup without interrupting plant shut downs. This automated, non-intrusive cleaning solution allows for round-the-clock maintenance, which eliminates the need for costly manual cleanings and extends the time between shutdowns.

As a result, Jaycorp’s boilers maintain higher thermal efficiency and operational reliability, enabling the plant to meet increased steam production demands efficiently.

Read more about Aerovit ShockClean System and discover all the advantages.

Overview

Jaycorp Green Energy, a subsidiary of Jaycorp Group in Malaysia, had long struggled with maintaining efficient operations at its biomass steam plant. Established in 2002, the plant faced financial challenges, particularly after switching to more economical fuel sources like empty fruit bunch fibers, which led to significant soot buildup in the fire tubes of their combi boilers. This clogging not only reduced efficiency but also forced the plant into frequent manual cleanings, disrupting operations and increasing costs.

By 2021, Jaycorp recognized the need for a strategic turnaround to address ongoing operational challenges. A key priority was finding an effective solution to the persistent boiler inefficiency and soot buildup, which forced the plant to shut down every three weeks for manual cleaning. These frequent shutdowns severely disrupted production, particularly affecting their palm oil refining clients who required a continuous and reliable steam supply.

Download the case story

Discover how we helped Jaycorp to achieve a more efficient production.