E.ON, Sweden

The Challenge

E.on faced challenges before installing Aerovit at their 4 boilers at plants in Värnamo, Rörvik, and Älmhult. All plants required frequent manual cleanings which led to operational disruptions, increased labor hours, and inefficiencies caused by soot accumulation.

Flue gas temperatures rose rapidly between manual cleanings, reducing boiler performance and increasing fuel consumption.

Before Aerovit

At Värnamo, Boiler 1 and Boiler 2 required cleaning every six weeks, whilst the boiler at Rörvik needed to be cleaned 10 times per year. In Älmhult, the boiler was cleaned nine times annually.

The Solution

To address these issues, E.ON installed Aerovit Soot Blower system on four

biomass boilers across the three

locations.

The goal was to reduce soot buildup during operation, minimize manual

interventions, and improve overall

energy efficiency.

Each installation targeted boilers fueled by wood chips and running over 5,000 hours each annually.

Statement from E.ON

How does Aerovit Soot Blower work at E.ON?

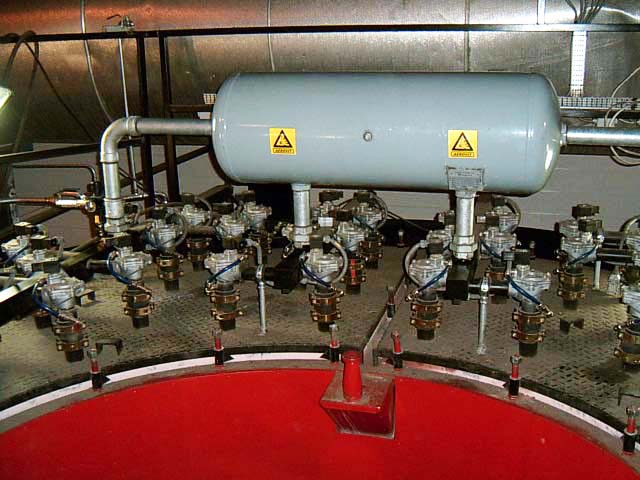

At each plant, the Aerovit system was mounted directly onto the boiler.

It works by sending short, powerful bursts of compressed air into the boiler to prevent soot and ash from settling on heat transfer surfaces. As a result, flue gas temperatures remain more stable, the boilers operate closer to optimal conditions, and the need for manual cleaning is drastically reduced. For example:

Värnamo Boiler 1: Reduced cleanings from 6 to 1 per year.

Rörvik Boiler 1: Reduced cleanings from 10 to 1 per year.

Älmhult Boiler 1: Reduced cleanings from 9 to 1 per year.

The Results

The operating managers at all three sites reported noticeable improvements in operational flexibility and efficiency. The soot blower system allowed them to plan maintenance around staff availability and weather, rather than necessity.

After the implementation of the Aerovit Soot Blower system, significant improvements were seen across all three locations:

In Värnamo, Boilers 1 and 2 required manual cleaning only once per year, compared to six times previously. The system delivered 1% fuel savings, improved boiler efficiency, and reduced manual cleaning by over 80%, resulting in a payback period of just 16 months.

At Rörvik, manual cleaning was reduced by 90%, boiler efficiency improved, and 1% fuel savings were achieved. The investment paid for itself in 15 months.

In Älmhult, the Aerovit system reduced manual cleaning by 90%, delivered 1% fuel savings, and increased boiler efficiency, leading to a return on investment within 17 months.

Manual Cleaning Reduced by up to 90%

Stabilized Flue Gas Temperature

Return on Investment in 15–17 Months

Significant Savings

Overview

E.ON Sweden operates multiple district heating plants, including Värnamo, Rörvik, and Älmhult. All these plants faced challenges related to frequent manual boiler cleanings, increased flue gas temperatures, and decreased boiler efficiency due to ash and soot buildup.

E.ON decided to implement the Aerovit Soot Blower system across four boilers to reduce manual cleaning efforts and optimize boiler performance. The investment proved successful, paying off in just 15–17 months and significantly reducing maintenance.

Download the case story

Discover how we helped E.ON to boost efficiency with an Aerovit Cleaning Solution.