Aerovit Type R

High impact 360° cleaning in hard to access areas in watertube boilers, evaporators and economizers.

The Aerovit Type R is an advanced rotating boiler cleaning solution based on the Aerovit Soot Blower.

The Aerovit Type R is designed specifically for boilers with limited installation space. This cleaning solution incorporates four synchronized Aerovit A40 valves to deliver powerful 360° cleaning coverage.

By releasing high-compressed air in a split second the Aerovit Type R generates a shock wave, that removes ash and soot between boiler tube sections before it settles.

The rotating functionality ensures thoroughly cleaning of hard to access areas, significantly reducing the need for manual intervention.

The Aerovit Type R operates during normal boiler conditions and requires no shutdowns, maintaining consistent cleanliness and optimal heat transfer efficiency throughout the boiler.

Features:

- Rotating 360° high impact cleaning

Ensures full cleaning coverage in narrrow and hard to acccess areas. - Increased boiler efficiency and output

- Enhances heat transfer and boosts boiler performance.

- Reduce downtime and maintenance

Less need for manual cleaning or unplanned shutdowns. - Reduce fuel consumption per produced MW

Optimizes use of fuel for energy production. - Energy savings and reduce CO2 emissions

Supports sustainability by lowering fuel consumption. - Compact installation

Requires minimal installation space.

The impact of soot buildup in water tube boilers

Soot accumulation in water tube boilers significantly reduces heat transfer efficiency by acting as an insulating layer on tube surfaces. This results in higher fuel consumption, increased flue gas temperatures and uneven thermal distribution.

Soot and ash will buildup continously and lead to reduced output, increased operational costs, and unscheduled shutdowns for manual cleaning or repair.

Keeping the boiler clean is important to maintain optimal boiler performance and reliability.

Application

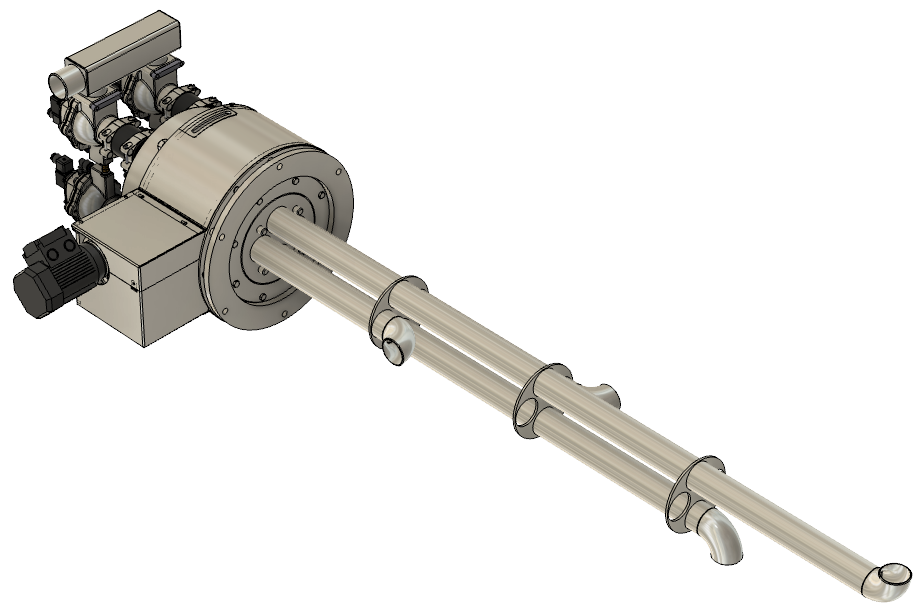

The Aerovit Type R is installed between the boiler tube sections.

The temperature of the flue gas should be kept at a constant level. This is ensured by activating the Aerovit Type R according to fuel and boiler design.

The soot and ash in the boiler should be dry and removable. If the deposits tend to be sticky or melting, the cleaning effect may be reduced.

Maximum length of the rotating pipe unit is 2,5m. The distance between the tube banks is recommended to be min 600mm. A 290mm inlet hole is needed for flanging the Aerovit Type R to the heat exchanger.

How does the Aerovit Type R work?

The Aerovit Type R utilizes powerful shock waves of high-compressed air to remove ash and soot between boiler tube sections.

In a split second, a large volume of high-compressed air is discharged through the Aerovit A40 valves, generating a powerful shock wave for effective 360° cleaning inside water tube boilers, economizers, or evaporators.

Get our product sheet

Download our product sheet with information about Aerovit Type R Cleaning Solution.